The equipment adopts an automatic cutting process equipment that combines pneumatic robotic arms and cutting arms. By pushing and pulling the cylinder, the high-speed rotating cutting arm is moved to the object to be cut for cutting work. The cutting head is used to identify CRT tubes of different sizes through its own profiling, and the edges are automatically cut, effectively separating the screen glass and cone glass.

A CRT (Cathode Ray Tube) Waste Picture Tube Automatic Cutting Machine is a specialized piece of equipment used in the recycling or disposal process of cathode ray tubes, which are found in older televisions and computer monitors.

Here's how it typically works:

Feeding: The waste picture tubes are fed into the machine either manually or through an automated conveyor belt system.

Detection and Sorting: The machine may incorporate sensors or cameras to detect and sort different types and sizes of CRTs. This sorting is important because different CRTs may require different cutting methods.

Cutting: Once sorted, the CRTs are positioned for cutting. The machine employs various cutting mechanisms such as saws, blades, or wire cutting techniques to safely sever the glass portion of the CRT from the rest of the electronics.

Separation: After cutting, the glass portion, which contains hazardous materials like lead, is separated from the other components. This separation is crucial for proper recycling or disposal.

Processing: Depending on the recycling facility's capabilities, the separated glass may undergo further processing, such as crushing and refining, to extract valuable materials like lead or to render the glass suitable for use in other products.

Disposal or Recycling: The remaining components, such as the plastics and metals from the CRT, are further processed for recycling or disposed of according to environmental regulations.

These machines are essential for safely and efficiently managing CRT waste, which can pose environmental and health hazards if not handled properly. They help streamline the recycling process and ensure that valuable materials are recovered while minimizing harm to the environment.

Description

using nichrome belt heating method can efficiently separate the glass panel and funnel, collect internal phosphor to prevent environmental pollution efficiently. Mainly used for waste TV with size 14-40"(Changes the length of heater band can cut a bigger size of TV), and waste computer monitors. The capacity for process the CRT from14’ to 40” can reaches 40 pieces per hour Single unit.

The whole plant Specifications:

Model | CRT Cutting System |

Type | Diamond Cutting |

Total Power | 15KW below |

Air compressor Model | W-0.8/12.5-7.5KW-180L |

Phosphor Powder collector Model | 60L-1.8KW->17KPa |

Capacity | 80-100set/H |

Applicable Scope | TV and computer: 14”~33”(7~50kg) |

Weight | 300KG |

Overall Size(mm) | 4080*800*1530 |

CRT Diamond Wheel cutting equipment cuts CRT into funnel and panel by using a cutting wheel.

OVERVIEW |

CRT Auto Cutter is a E-waste recylcing device. It cuts CRT into funnel and panel.

· Quickly cuts CRT into funnel and panel

· Physical cutting method ensures high cutting speed

· Easy to operate, reduce labor intensity

· Capacity up to 120 units per hour

· Environmental friendly

Composition |

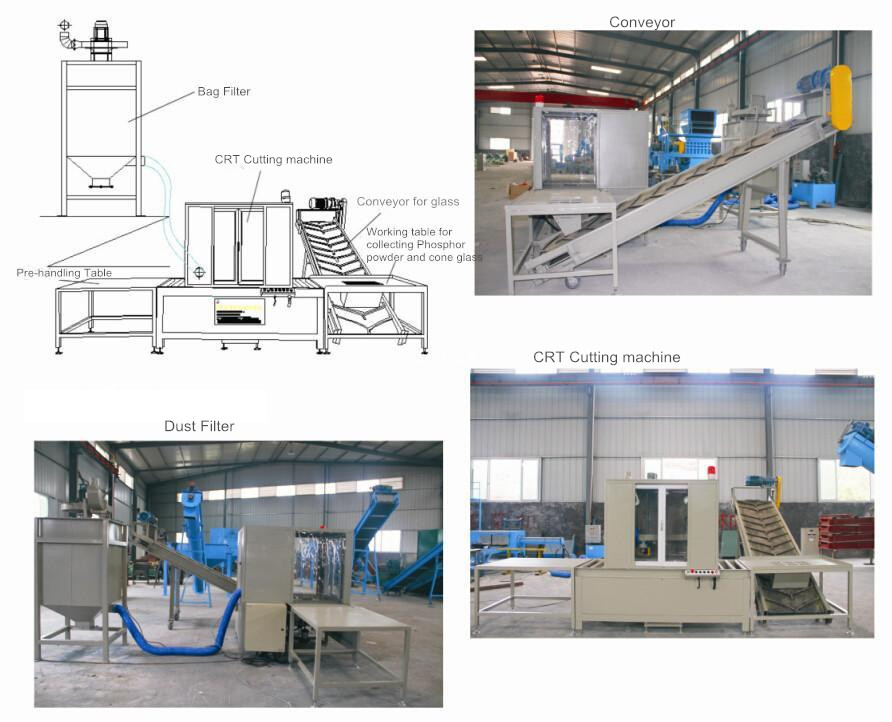

CRT Auto Cutter consists of cutting device, dust collection equipment, out-feed belt conveyor, explosion-proof belt cutting table, glass recycling workbench components.

Working Flow |

After removing steel belt/explosion-proof belt, operator places the CRT on the cutting table making the CRT center just

facing the vacuum adsorption device, then start vaccum adsorption device to fasten the CRT, at the same time infrare

is automatically open shooting to the CRT as a reference line for cutting, after that the operator will press height adjust

button to slightly move up/down the CRT according to the infrared reference line. After all these done, start cutting

process by press a button, a cutting wheel cuts the CRT as per the infrared line, 25 secondes later, funnel and panel are separated.

SPECIFICATIONS |

Size | 4800*3100*2350mm | Air Pressure | 0.6~0.8MPa |

Capacity | 100~120 units/h | Power | 380V/8.05kw |

Operators | 3 | Applicable Items | 14~32 inch CRT |

Working Voltage | AC380V+/-10% 50HZ | |

|

Belt MX800

Motor power:1.5KW

Rotation runs: 40r/m

Weight:600KG

CRT waste picture tube automatic cutting machine-Products-Jiangxi Mingxin

CRT waste picture tube automatic cutting machine-Products-Jiangxi Mingxin