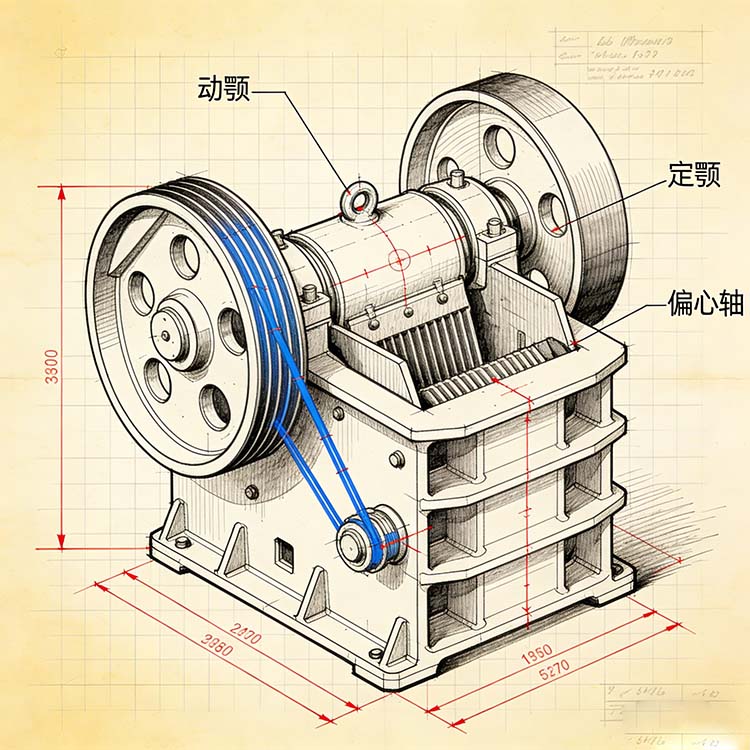

A jaw crusher is a heavy-duty machine used primarily in the mining, construction, and recycling industries to break down large rocks and materials into smaller, more manageable pieces.1 Often called "primary crushers," they are the first step in the material reduction process.2How It Works: The "Nutcracker" PrincipleThe machine operates using compressive force.3 It features a V-shaped crushing chamber formed by two vertical jaw plates:4Fixed Jaw: Remains stationary, attached to the crusher's frame.5Swing (Movable) Jaw: Moves back and forth against the fixed jaw.6As the swing jaw moves toward the fixed jaw, it compresses the material.7 When it moves away, the crushed material falls further down the chamber until it is small enough to pass through the discharge opening at the bottom.8Key ComponentsEccentric Shaft: Driven by a motor, this shaft creates the oscillating motion of the swing jaw.9Flywheels: Large, heavy wheels on the ends of the shaft that store kinetic energy to maintain a steady crushing rhythm.10Toggle Plate: Acts as a safety "fuse."11 If a non-crushable object (like a piece of steel) enters the chamber, the toggle plate is designed to snap, protecting the expensive shaft and motor from damage.12Jaw Plates (Liners): Usually made of high-manganese steel, these are the replaceable wear parts that actually come into contact with the rock.Types of Jaw CrushersTypeBest ForMechanismSingle ToggleMedium-hard materials; general construction.Lighter and cheaper; jaw moves in an elliptical "rocking" motion.Double ToggleExtremely hard or abrasive rocks (granite, ore).Heavy-duty; jaw moves in a pure pendulum motion, reducing wear.Pros and ConsAdvantages:Reliability: Extremely robust and can handle very large, tough feed material.13Simple Design: Easy to operate and maintain compared to complex secondary crushers.14Cost-Effective: Lower initial investment and operating costs for primary reduction.15Disadvantages:Product Shape: Tends to produce "flaky" or irregular-shaped stones rather than perfect cubes.Noise and Dust: Generates significant noise and fine dust during operation.16Limited Fineness: Cannot produce very small or fine gravel; usually requires a secondary crusher (like a cone or impact crusher) to follow it.17Would you like me to compare jaw crushers with other types, such as cone or impact crushers, to see which fits a specific project?Jaw Crusher Working Principle AnimationThis video provides a clear animation of how the eccentric shaft and toggle plates coordinate to move the swing jaw and crush material.

Jaw crusher-Products-Jiangxi Mingxin

Jaw crusher-Products-Jiangxi Mingxin